FOSFOMATIC system

ADDITIONAL INFORMATION

category: materialsMethods of scanning phosphorous plates.

Some of key features of the digital radiography complex inevitably imply from the already selected method for phosphorous plates scanning.

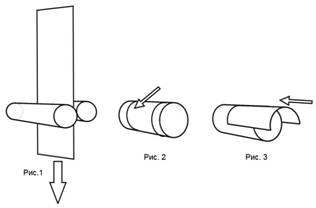

For example, if during the scanning process the sensitive layer of the plate frictionizes the fixed surface, like it is shown on fig. 3, it has to expect on the X-ray images the appearance of scratches already after some exposures. It is doubtful whether it would be possible to pass the roll plate through such unit without any sharp bends due to the bending around the longitudinal axis. We don’t use such method.

For example, if during the scanning process the sensitive layer of the plate frictionizes the fixed surface, like it is shown on fig. 3, it has to expect on the X-ray images the appearance of scratches already after some exposures. It is doubtful whether it would be possible to pass the roll plate through such unit without any sharp bends due to the bending around the longitudinal axis. We don’t use such method.

The scanner with rotary drum (fig.2) is compact and light and at the same time it even excludes any touching of sensitive plate layer during the reading; which increases the service life of the plates in many times. Its disadvantage like that of the model mentioned above consists in the restriction on scanning plates dimensions. We use this method only in the model FOSFOMATIC-21M.

The scanner with vertical roll plate feed (fig. 1) provides the processing without any restrictions in the sizes of plates produced. Rolls don’t attrite on the plate surface but run on it, so the plate damage during the scanning takes place extremely seldom. This method is used in all scanners FOSFOMATIC.

Comparison of the digital radiography method and method of traditional radiography with subsequent digitization of radiographic films.

Obvious advantages of digital radiography consist in the denunciation from consumables and wet film processing, consequently, in the increase of control rate and in the cost reduction.

After entering the image into the computer, it seems to be not so important what was its source – radiographic film or phosphorous plate. However, it is far from true.

First, the image from the phosphorous plate has much bigger dynamic range. So, the complex FOSFOMATIC allows obtaining on one radiograph the high-quality images of the zones that have received exposure doses, which differ up to thousand times between them; while for the films the difference between exposure doses only in 3-6 times corresponds to the range of optic densities from 1.5 to 3.5 suitable for the interpretation.

Consequence №1 – technology FOSFOMATIC makes much easier the work of radiographer at the stage of exposure time selection. The need in “re-scanning” underexposed or overexposed films as well as those spoiled during the development.

Consequence №2 - technology FOSFOMATIC allows the inspection of products having big differences of radiation thickness under one exposure (instead of several exposures like it happens when the film is used).

Second, the process of film scanning is inevitably related to a certain extent to the loss of image quality. Scanners, applied for the digitization are not suitable for the operation with films which density exceeds 3.5. Any change in the adjustments of the scanner can result in the distortion of the information being transferred to the computer, which reduces the authenticity of the interpretation.

Finally, the process of film scanning aggravates much more the disadvantages of film radiography that are related to the waste of time and human labor.